This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/

K3에 축적된 내부 응력이 피로 파절에 미치는 영향

Effect of internal stress on cyclic fatigue failure in K3

Jun-Young Kim, Jin-Woo Kim, Kyung-Mo Cho, Se-Hee Park*

Department of Conservative Dentistry, Gangneung-Wonju National University School of Dentistry, Gangneung, Korea

Objectives: This study aimed to evaluate the relationship between the cyclic fatigue of a K3 file and internal stress intentionally induced until the activation of the auto- stop function of the torque-controlled motor. Materials and Methods: K3 (Sybron Endo) .04 and .06 taper, size 25, 30, 35, 40 and 45 were used in this study. To give the internal stress, the K3 files were put into the .02 taper Endo-Training-Bloc (Dentsply Maillefer) until the activation of the auto-stop function of the torque-controlled mo- tor. The rotation speed was 300 rpm and torque value was 1.0 N·cm. K3 were grouped by the number of induced internal stress and randomly distributed to 4 experimental groups (n = 10, Stress 0 [control], Stress 1, Stress 2 and Stress 3). For measuring the cyclic fatigue failure, the K3 files were worked against a sloped glass block and time for file separation was recorded. Data was statistically analyzed Statistical analyses were performed using two-way ANOVA and Duncan post-hoc test at p < 0.05 level. Results:

Except .04 taper size 30 in Stress 1 group, there were statistically significant differ- ences in time for file separation between control and all experimental groups. K3 with .04 taper showed higher cyclic fatigue resistance than those of .06 taper. Conclusion:

In the limitation of this study, the cyclic fatigue of the K3 file was influenced by the accumulated internal stress from use until the auto-stop function was activated by the torque-controlled motor. Therefore, clinicians should avoid the reuse of the K3 file that has undergone auto-stops. (Restor Dent Endod 2012;37(2):74-78)

Key words: Auto-stop; Cyclic fatigue failure; Internal stress; K3; Separation; Torsional stress

서론

회전식 니켈-티타늄파일은 같은크기의스테인레스스틸파일에비해구부림(bending)이나뒤틀 림(torsion)에2 - 3배의탄성을가지고있어, 만곡된근관에서도근관성형전의근관형태를유지하 고근관에가해지는힘을최소화하여작업장의변화나치근단공변위(apical transportation)와같은문 제점을효과적으로감소시킨다는장점이있다.1-4그러나초탄성의특징에도불구하고회전식니켈-티 타늄파일은근관치료중근관내에서파절이일어날수있는위험성이항상존재한다. 대부분의스테 인레스스틸파일이과도한토크에의해파절되는데반해회전식니켈-티타늄파일의파절은비틀림 (torsion)과피로(fatigue)에의해일어난다.5기구의일부가좁고만곡된근관에꽉낀상태에서전기 김준영, 김진우, 조경모, 박세희*

강릉원주대학교치과대학치과보 존학교실

Received December 22, 2011;

Revised February 6, 2012;

Accepted February 12, 2012.

Kim JY, DDS, MSD, Resident; Kim JW, DDS, PhD, Professor; Cho KM, DDS, PhD, Associate Professor; Park SH, DDS, PhD, Assistant Professor, Department of Conservative Dentistry, Gangneung-Wonju National University School of Dentistry, Gangneung, Korea

*Correspondence to Se-Hee Park, DDS, PhD.

Assistant Professor, Department of Conservative Dentistry, Gangneung- Wonju National University School of Dentistry, 120 Daehang-ro, Gangneung, Korea 210-702 TEL, +82-33-640-2760; FAX, +82- 33-640-3103; E-mail, drendo@

gwnu.ac.kr

※This study was supported by research funding of 2011 year from Gangneung-Wonju National University Dental Hospital (2011-0089).

ISSN 2234-7658 (print) / ISSN 2234-7666 (online) http://dx.doi.org/10.5395/rde.2012.37.2.74

모터가계속회전하면기구에작용하는비틀림응력이기구가가진최 대전단응력을넘어서게되고기구는비틀림파절(torsional fracture)

을일으킨다.6회전식 니켈-티타늄파일의주기적 피로파절(cyclic

fatigue fracture)은최대만곡부위에서신장력과압축력의반복으로

인해발생한다.7피로란항복점(yield point) 이하에서지속적인응력 을받는것을의미하며, 주기적피로란만곡된근관에서계속된회전 에의해생긴파일의물성저하를나타내기위해사용되어왔다.8이러 한파절이발생하는데는다양한요인이작용한다.5

파일단면형태가기구의뒤틀림과굽힘스트레스에영향을미칠수 있으며큰단면적을가질수록더큰 내부응력(internal stress)이축 적될수있고, 축적된응력의확산은표면결함이있는경우더 빠르 게진행될수있어더빠른파절을야기하게된다.7,9임상에서응력의 축적을감지하기가쉽지않은데, Gambarini는토크조절전기모터 (torque-controlled motor)를사용할경우설정된토크이상의힘이기

구에부여되면기구의회전이멈추거나(auto-stop), 반대로회전하여

(auto-reverse) 술자가응력의축적을감지할수있고기구에부여되는

과도한응력을막아주기때문에기구의파절가능성을낮춰준다고보 고하였다.10

회전식니켈-티타늄파일은스테인레스스틸파일과는달리뒤틀림 이나구부러짐등의전구증상없이파절이 일어난다.7즉, 외형적인 변형없이내부응력이축적되어기구의수명이단축될수있다.11기구 의수명은주기적피로파절저항성으로측정할수있으며, 미리부여 된비틀림응력이주기적피로파절저항성을유의하게감소시킨다는 보고가있다.12기구의파절을예방하고수명을증가시키기위해새로 운단면형태를갖는회전식니켈-티타늄파일이소개되고있다. 제조 사에따르면 Positive rake angle을 가지는 K3 (Sybron Endo, Orange, CA, USA)는 길이에따라코어직경(core diameter)이달라짐으로써 기구의유연성이증가하고세개의비대칭 radial land와 radial land

relief를가짐으로써근관벽으로부터기구에부여되는응력을효율적

으로분배하고감소시킨다. 따라서본실험에서토크조절전기모터

의 auto stop을 통해비틀림에의한내부응력을의도적으로부여한

다음, 이런내부응력이 K3의주기적피로파절에미치는영향을연구 하고자하였다.

연구 재료 및 방법

본 실험에사용된회전식 니켈-티타늄파일은 21 mm 길이의 .04, .06 taper K3이며, 25, 30, 35, 40그리고45번의다섯가지크기를사 용하였다. 전기모터는 X-SMART(Dentsply Maillefer, Ballaigues, Swit- zerland)를사용하였다. 회전식니켈-티타늄파일에내부응력을부여 하기위한레진모형근관으로 .02 taper Endo-Training-Bloc (Dentsply Maillefer)을사용하였다.

회전식니켈-티타늄파일을임의로10개씩3개의실험군으로나누 었으며횟수를달리하여내부응력을부여하였다. 내부응력을 부여 하기위한전기모터의속도는300 rpm, 토크값은1.0 N·cm, auto- stop으로설정하였다. Endo-Training-Bloc을바이스에단단히고정한 후, 파일에가해지는응력이설정된토크값을넘어서회전이멈출때 까지 K3파일을모형근관에일정한힘으로밀어넣었다. 각각의파일 에내부응력을부여할때는모두새모형근관을사용하였고, 모든과 정은숙련된한사람의임상가가수행하였다. 각각의실험군(n = 10)

에내부응력을1회에서3회까지부여하였으며(Stress 1군, Stress 2군, Stress 3군), 대조군(Stress 0군)에는내부응력을부여하지않았다. 내 부응력을부여하는과정에서파절이나변형이일어난파일은피로파 절측정에서제외하였다.

피로파절의측정은 Li 등이사용했던경사진면에기구를회전시키 는 방법을응용하였으며, 파일과유리판이이루는각도는60°로설정 하였다.13내부응력을부여한회전식니켈-티타늄파일을고정된전기 모터에 장착하여설정된각도로 경사진유리판과접촉시켰다(Figure 1). 유리판과접촉하는회전식니켈-티타늄파일의길이는파일첨부터 약3 mm이며, 파일이회전하는동안파일의변위를막기위해유리판 에1 mm 깊이의구를형성하였다. 유리판과파일의마찰부위에윤활 제를도포하여마찰력이실험결과에미치는영향을최소화하였다. 회 전하기시작한때부터파일의파절시간을기록하였다.

회전식니켈-티타늄파일이파절된후, 파절단면과측면을전계방 출 주사전자현미경(Field emission scanning electron microscope, FE-SEM, SU-70, Hitachi, Tokyo, Japan)을이용하여관찰하였다. 대조 군을포함한모든실험군의파절시간을 SPSS version 19.0 (SPSS Inc., Chicago, IL, USA)을사용하여 two way ANOVA test로비교분석하였 으며 Duncan test를이용하여95% 유의수준에서사후검정하였다.

결과

K3각크기에따른파절시간의평균과표준편차를 Table 1과2에 나타내었다.

K3 .04 taper 30번(Stress 1군)을제외한모든실험군에서대조군과 비교할때, 파절시간이유의하게감소하였다. K3 .04 taper 파일의크 Figure 1. Representative image of cyclic fatigue test (inclined glass plane).

60˚

기가커질수록파절시간이증가하였다. .06 taper의모든실험군에서 대조군에비하여파절시간이통계적으로유의하게감소하였으며같 은크기를가진파일의실험군간의유의한차이는관찰되지않았다.

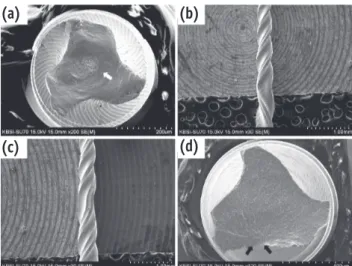

.04 taper 25번의실험군중하나의파일은내부응력을가하는중 에파절되었으며주사전자현미경분석에서중앙부위의다수의딤플 을 보이는연성파괴와주변부위의평탄한면이관찰되는전형적인 비틀림응력에의한파절양상이관찰되었다(Figure 2a). .04 taper 25 번과30번의실험군중 각각하나의파일에서내부응력을부여하는 과정중변형이관찰되어피로파절실험에서제외하였다(Figures 2b and 2c).

파절단면의주사전자현미경분석결과, 피로파절검사를시행한 모든군에서비틀림 응력에의한파절양상은관찰되지않고균열의 급속한진행을나타내는방사상의선조와넓은면에딤플을보이는주 기적피로파절양상만관찰되었다(Figure 2d).

총괄 및 고안

회전식니켈-티타늄파일은전구증상없이파절이일어나기때문 에 파일의변형이나표면결함과같은파일의외적인모습으로파절 을 예측하기힘들다.7따라서 파일에 미리부여된 비틀림응력이 내 부응력으로작용할수있을것으로생각되어본실험을통해비틀림 응력과 피로파절저항성의관계를 연구하고자했다. 예비실험에서

auto-reverse로설정하였을때파일이반대방향으로회전하면서오히

려너무큰응력이파일내에작용하여비틀림파절을겪었기때문에 본실험에서비틀림응력을내부응력으로이용하기위해전기모터의 auto-stop 기능을이용하였다.

Figure 2. FE-SEM view of K3. (a) Torsional fracture of K3 .04/#25. Central dimples and circular abrasion mark (white arrow) (×200); (b) Torsional distorsion of K3 .04/#25;

(c) Torsional distorsion of K3 .04/#30 (×30); (d) Cyclic fatigue fracture of K3 .04/#45. Radial striations linked at a point on the edge (black arrow) (×120). The surfaces of cyclic fatigue fracture in all experimental groups showed same patterns. FE-SEM, field emission scanning electron microscope.

(a) (b)

(c) (d)

Table 1. Time for file separation of K3 .04 taper

Group #25 #30 #35 #40 #45

No. Mean (sec) No. Mean (sec) No. Mean (sec) No. Mean (sec) No. Mean (sec)

Stress 0 10 445.49 ± 100.48a 10 660.93 ± 81.60a 10 954.21 ± 60.04a 10 1254.44 ± 76.18a 10 1157.71 ± 170.99a Stress 1 9 332.54 ± 92.90b 10 670.69 ± 74.74a 10 762.72 ± 116.69b 10 782.90 ± 214.35b,c 10 965.30 ± 61.36b Stress 2 10 339.38 ± 50.08b 10 576.69 ± 103.61b 10 644.92 ± 129.37c 10 882.27 ± 139.30b 10 753.94 ± 68.22c Stress 3 9 266.89 ± 74.72b 9 513.15 ± 105.36b 10 586.37 ± 143.62c 10 701.91 ± 287.60c 10 812.48 ± 68.83c Same superscripts shows no statistically significant difference in same size.

Stress 0 group was not induced internal stress, Stress 1 group was induced internal stress 1 time, Stress 2 was induced internal stress 2 times, and Stress 3 was induced internal stress 3times by activation of the auto-stop function of the torque-controlled motor.

Table 2. Time for file separation of K3 .06 taper

Group #25 #30 #35 #40 #45

No. Mean (sec) No. Mean (sec) No. Mean (sec) No. Mean (sec) No. Mean (sec)

Stress 0 10 131.50 ± 31.80a 10 204.30 ± 30.04a 10 152.81 ± 42.42a 10 152.78 ± 31.25a 10 146.29 ± 51.86a Stress 1 10 87.44 ± 19.87b 10 116.62 ± 22.43b 10 76.79 ± 10.59b 10 99.02 ± 13.09b 10 98.13 ± 20.95b Stress 2 10 88.74 ± 7.18b 10 101.45 ± 26.43b 10 91.43 ± 18.51b 10 103.60 ± 16.97b 10 90.97 ± 7.37b Stress 3 10 95.72 ± 12.73b 10 100.77 ± 12.14b 10 81.18 ± 9.58b 10 97.61 ± 9.34b 10 84.97 ± 26.49b Same superscripts shows no statistically significant difference in same size.

Stress 0 group was not induced internal stress, Stress 1 group was induced internal stress 1 time, Stress 2 was induced internal stress 2 times, and Stress 3 was induced internal stress 3times by activation of the auto-stop function of the torque-controlled motor.

회전식니켈-티타늄파일을회전시킬때 일정한속도와토크값의 유지를위해전기모터를사용하고있다.14제조사에따르면 K3를임상 적으로사용할때, 전기모터의속도는300 rpm, 토크값은1.5 N·cm 이상으로사용할것을추천하고있다. 그러나본연구에서는전기모 터의속도는300 rpm, 토크값은1.0 N·cm으로설정하였다. 예비실 험에서전기모터의 속도는300 rpm, 토크값은1.5 N·cm으로내부 응력을부여한결과, 파일에가해지는과도한응력으로여러파일이 파절되거나변형되었다. 이러한파절이나변형은내부응력을부여하 고자하는본연구의목적에맞지않는것으로생각되어변형이나파 절을유발하지않고내부응력만부여할수있도록1.0 N·cm으로낮 추어설정하였다. 내부응력을부여하는과정에서 .04 taper 25번에서 하나의표본이파절되었고 .04 taper 25번과30번에서각각하나의표 본이변형되었다. 작은직경의회전식니켈-티타늄파일이비틀림응

력에대한저항성이낮은것으로생각할수있으며, 이는 Melo 등의연

구결과와일치하였다.15주사전자현미경분석결과, 비틀림응력에 의해파절된기구의단면은중앙부위에딤플이관찰되는연성파괴와 그주변부로동심원상의마찰자국과평탄한면을나타내는전형적인 비틀림파절양상을나타냈다(Figure 2a).

Endo-Training-Bloc을이용하여내부응력을부여했을때파일첨으 로부터4 - 8 mm 부위에레진잔사가가장많이묻어나왔다. 이부위 에가장많은내부응력이축적되었을것으로생각되므로주기적피로 파절검사에서파일이유리판과3 mm 접촉하게하여파일의최대만 곡부위를파일첨4 - 8 mm 부위에위치하도록설정하였다.

회전식 니켈-티타늄파일의 피로파절을 측정하는다양한 방법이 소개되어왔다.16 Pruett 등은초기의회전식니켈-티타늄파일을이용 하여만곡된금속관에파일이금속관에꽉끼지않게하여피로파절 을측정하였다.7,17그러나이러한실험설계는보통같은크기의관이 사용되기때문에작은기구는큰기구보다더적게변형되고만곡반 경은더크게되어큰기구보다작은기구에서더긴 피로수명이나 타날것으로사료된다.17 Haïkel 등은 grooved block-and-rod를이용하 여스테인레스스틸기구의피로파절을측정하였다.18그리고이를회 전식니켈-티타늄파일에도적용하였으나연구에서파일과장치간의 접촉상태에대해언급하지않았으며매실험마다같은위치에기구를 위치시키는등의실험조건을동일하게하기가어려웠다.19오래전부

터기계공학에서사용되는피로파절검사법인삼점굽힘(three point

bending)에의한검사는 Cheung과 Darvell 에의해비교적최근에연 구되었다.20그러나이러한방법도파일간의서로다른휨성질과같은 파일이더라도파일의위치에따라다른휨성질을갖게되므로정확한 만곡궤도를재현할수없는것으로생각된다. 본연구에서사용한경 사진유리판에서파일을회전시키는방법은비교적장치설계가간단 하며, 다른측정방법에비해마찰에의한기구의손상을줄일수있고 만곡각도를일정하게재현할수있다는장점이있다. 그러나단면적 의크기가작은기구는큰기구보다유연하기때문에만곡반경이작 아지고더큰피로응력이부여될수있다.13,16그러한만곡반경및만 곡궤도의차이를줄이기위하여경사진유리판에1 mm 깊이의구를 형성하여기구가유리판과동일한접촉면적을가지고일정한위치를 갖도록하였다.

Melo 등은 K3를이용하여회전식니켈-티타늄파일의특성을연구

하였는데, 파일의직경과단면적이증가할수록 기구의유연성이 유 의하게감소하였으며 이로인해기구의피로파절 저항성이떨어질

수있다고보고하였다.15본연구에서는전체적으로파일의파절시간

은 .04 taper에서길게측정되었으며이는작은파일단면적으로인한

유연성 증가에서기인한것으로생각되며기존의연구들과일치하였 다.11,14 .06 taper의모든실험군에서같은크기를가진파일의실험군 간의유의한차이는관찰되지않았다. 즉, .06 taper에서내부응력의 횟수가중요한것이아니라내부응력을받았는지, 안받았는지가결과 에중요한영향을미치는것으로생각된다.

Melo 등과 Schäfer 등은회전식니켈-티타늄파일은단면적크기와 디자인에따라서물리적인성질이다르다고보고하였다.15,21실제로본 연구의예비실험에서20번크기의파일은다른크기의파일에비하여 비틀림저항성은매우낮게측정되었으며피로파절저항성은매우높 게측정되었다. 임상에서도단면적의크기가작은파일은주기적피로 파절이 발생하는경우가거의없다.7,19,22따라서본 연구에서도20번 크기의파일은실험에서제외하였다.

주기적피로파절단면의주사전자현미경분석결과, 주기적피로 파절양상만관찰되었고실험군과대조군의파절단면양상은유의한 차이가관찰되지않았다. 회전식니켈-티타늄파일표면에발생한표 면결함이파일의균열발생및진행에영향을주어주기적피로파절 저항성을낮출수있다.23,24따라서본연구에서비틀림응력이가해졌 을때표면결함이발생하여주기적피로파절저항성에영향을줄수 있다고생각하였으나, 대조군에비하여실험군에서표면결함이나균 열의증가는관찰할수없었다.

본연구에서비틀림저항으로인한내부응력이피로파절에영향을 주는것으로관찰되었으며, 실제임상에서비틀림파절과피로파절이복 합적으로나타나는경우가많고그경계를구분하는것은매우어렵다. 따라서파일의파절을막기위해두가지요인을모두고려해야한다.

결론

의도적으로 K3에서로다른횟수의내부응력을부여한후, 그파일 의피로파절을측정함으로써내부응력과피로파절의관계를평가한 결과근관형성과정에서 auto-stop이발생하였거나근관내에서그에 상응하는비틀림응력이부여되었다면그파일을재사용하는데 있어 서주의해야할것으로사료된다.

Conflict of Interest: No potential conflict of interest relevant to this article was reported.

References

1. Walia HM, Brantley WA, Gerstein H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J Endod 1988;14:346-351.

2. Gambill JM, Alder M, del Rio CE. Comparison of nickel- titanium and stainless steel hand-file instrumentation using computed tomography. J Endod 1996;22:369-375.

3. Glossen CR, Haller RH, Dove SB, del Rio CE. A comparison of root canal preparations using Ni-Ti hand, Ni-Ti engine-driven, and K-Flex endodontic instruments.

J Endod 1995;21:146-151.

4. Elliott LM, Curtis RV, Pitt Ford TR. Cutting pattern of

nickel-titanium files using two preparation techniques.

Endod Dent Traumatol 1998;14:10-15.

5. Cheung GSP. Instrument fracture: mechanisms, removal of fragments, and clinical outcomes. Endodontic Topics 2009;16:1-26.

6. Kramkowski TR, Bahcall J. An in vitro comparison of torsional stress and cyclic fatigue resistance of ProFile GT and ProFile GT Series X rotary nickel-titanium files. J Endod 2009;35:404-407.

7. Pruett JP, Clement DJ, Carnes DL Jr. Cyclic fatigue testing of nickel-titanium endodontic instruments. J Endod 1997;23:77-85.

8. Sattapan B, Nervo GJ, Palamara JE, Messer HH. Defects in rotary nickel-titanium files after clinical use. J Endod 2000;26:161-165.

9. Kuhn G, Tavernier B, Jordan L. Influence of structure on nickel-titanium endodontic instruments failure. J Endod 2001;27:516-520.

10. Gambarini G. Advantages and disadvantages of new torque-controlled endodontic motors and low-torque NiTi rotary instrumentation. Aust Endod J 2001;27:99- 104.

11. Berutti E, Negro AR, Lendini M, Pasqualini D. Influence of manual preflaring and torque on the failure rate of ProTaper rotary instruments. J Endod 2004;30:228-230.

12. Barbosa FO, Gomes JA, de Araújo MC. Fractographic analysis of K3 nickel-titanium rotary instruments sub- mitted to different modes of mechanical loading. J En- dod 2008;34:994-998.

13. Li UM, Lee BS, Shih CT, Lan WH, Lin CP. Cyclic fatigue of endodontic nickel titanium rotary instruments: static and dynamic tests. J Endod 2002;28:448-451.

14. Park SH, Seo HW, Hong CU. An evaluation of rotational stability in endodontic electronic motors. J Korean Acad Cons Dent 2010;35:246-256.

15. Melo MC, Pereira ES, Viana AC, Fonseca AM, Buono VT, Bahia MG. Dimensional characterization and mechani- cal behaviour of K3 rotary instruments. Int Endod J 2008;41:329-338.

16. Plotino G, Grande NM, Cordaro M, Testarelli L, Gambarini G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J Endod 2009;35:1469-1476.

17. Bahia MG, Buono VT. Decrease in the fatigue resistance of nickel-titanium rotary instruments after clinical use in curved root canals. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 2005;100:249-255.

18. Haikel Y, Gasser P, Allemann C. Dynamic fracture of hy- brid endodontic hand instruments compared with tradi- tional files. J Endod 1991;17:217-220.

19. Haïkel Y, Serfaty R, Bateman G, Senger B, Allemann C. Dynamic and cyclic fatigue of engine-driven ro- tary nickel-titanium endodontic instruments. J Endod 1999;25:434-440.

20. Cheung GS, Darvell BW. Fatigue testing of a NiTi rotary instrument. Part 1: strain-life relationship. Int Endod J 2007;40:612-618.

21. Schäfer E, Dzepina A, Danesh G. Bending properties of rotary nickel-titanium instruments. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 2003;96:757-763.

22. Ullmann CJ, Peters OA. Effect of cyclic fatigue on static fracture loads in ProTaper nickel-titanium rotary instru- ments. J Endod 2005;31:183-186.

23. Shin YM, Kim ES, Kim KM, Kum KY. Effect of surface defects and cross-sectional configuration on the fatigue fracture of NiTi rotary files under cyclic loading. J Ko- rean Acad Cons Dent 2004;29:267-272.

24. Lee JK, Kim ES, Kang MW, Kum KY. The effect of surface defects on the cyclic fatigue fracture of HEROShaper Ni-Ti rotary files in a dynamic model: a fractographic analysis. J Korean Acad Cons Dent 2007;32:130-137.