Chapter 10. Heat Transfer by Conduction

Three heat flow mechanisms:

Conduction (전도)

Convection (대류) natural convection (자연대류) Radiation(복사) forced convection (강제대류)

Basic Law of Conduction

* Fourier’s law

dx k dT dA

dq =−

q : rate of heat flow A: surface area T: temperature x : distance normal to surface k : thermal conductivity

--- Eq. (10.1)

General expressions of Fourier’s law in all three directions:

T z k

T y

T x

k T dA

dq ⎟⎟= − ∇

⎠

⎜⎜ ⎞

⎝

⎛

∂ + ∂

∂ + ∂

∂

− ∂

=

* Thermal conductivity (열전도도) k

dy µ du τ = − Fourier’s law에서의 비례상수

Å Newton’s law에서의 점도에 해당

Rate of heat flow (열흐름속도) q 의 단위: W or Btu/h dT/dx 의 단위: oC/m or oF/ft

∴ 열전도도 k 의 단위: W/m·oC or Btu/ft·h·oF For small ranges of T, k = constant

For larger T ranges, k = a + bT

solids: 17 W/m·oC for stainless steel 415 W/m·oC for silver

k values 0.35 W/m·oC for glass liquids: 0.5 W/m·oC for water gases: 0.024 W/m·oC for air

Solid having low k Æ “insulators” ex) polystyrene foam dx

k dT dA

dq =−

Steady-State Conduction ( 정상상태 열전도 )

Å neither accumulation nor depletion of heat within the slab q is constant along the path of heat flow

Heat flow into the tank Heat flow from the tank

B k T x x

T kT

dx k dT A

q = ∆

−

= −

−

=

1 2

1

2 --- Eq. (10.7) x: distance from hot side B: thickness of slab

R T A

q = ∆

thermal resistance (B/k) 1/R : conductance (k/B) cf.)

Ex. 10.1) A layer of pulverized cork (insulator)

0.152 m

T2 = 4.4 oC T1 = 82.2 oC

q = ?

k : 0.036 W/moC at 0 oC 0.055 W/moC at 93.3 oC A = 2.32 m2

q (the rate of heat flow) ?

W 3 . 53

152 . 0

8 . 77 0

3 . 93

036 . 0 055 . 3 0 . 43 036 . 0 32 . 2

=

⎟×

⎠

⎜ ⎞

⎝

⎛

−

× − +

×

∆ =

= B

k T A q

* Compound resistances in series

In steady heat flow,

C B

A q q

q = =

C B

A T T

T

T = ∆ +∆ +∆

∆

A k q B

A A A

A k q B

B

B B k A

q B

C C C

R T R

R R

T k

B k

B k

B

T A

q

C B

A C

C B

B A

A

= ∆ +

+

= ∆ +

+

= ∆

∴ / / /

&

C C B

B A

A

R T R

T R

T R

T = ∆ = ∆ = ∆

∆ A

q A q A q A

qA = B = C = ⇒

Ex. 10.2) A flat furnace wall constructed of a layer of Sil-o-cel brick backed by a common brick

BB = 0.229 m

T2 = 76.6 oC T1 = 760 oC

BA = 0.114 m Sil-o-cel

brick

common brick

Tx

kA = 0.138 W/m oC kB= 1.38 W/m oC kA kB

(a) Heat loss through the wall, q = ? Assume A = 1 m2

W 81 . 693 693.81W/m

5 683.4/0.98

C 683.4 C/W

m 985 . 0

159 . 0 826

. 0

2

o o

2

=

=

=

∴

=

∆

= +

=

=

=

=

=

q q/A

T R

R R

k R B

k R B

B A

B B B

A A A

(b) Temperature of the interface between the two bricks

C 186.9 C

08 . 573 826

. 0 / 985

. 0 / 4 . 683 /

/ = ∆ = ∆ ∆ = o ∴ = 1 ∆ = o

∆T R TA RA TA TA Tx T- TA

(c) In case that the contact between the two bricks is poor and the contact resistance is 0.088 m2 oC/W, the heat loss q = ?

W 9 . 636 /

C/W m

073 . 1 088 . 0 985 .

0 + = 2 o ∴ = ∆ =

= q T R

R

* Heat flow through a cylinder

Logarithmic mean radius vs. arithmetic mean radius cylinder length: L

dr

ro ri

) 2 ( rL dr

kdT

q = − π

i o

o i L

i o

o T i

T r

r

r r

T T A k

r r

T T L q k

q dT Lk r

dr o

i o

i

−

= −

= −

∫ ⇒

= −

∫

) (

) / ( ln

) )(

2 (

2π π

L r AL = 2π L

) / ( ln o i

i L o

r r

r r = r −

: logarithmic mean radius (로그평균반지름)

rL ra

Ex. 10.3) A tube of 60 mm OD insulated with a 50 mm silica foam layer and a 40 mm cork layer Calculate the heat loss q of pipe in W/m ?

For silica layer, kA = 0.055 W/m oC

kB= 0.05 W/m oC 50 mm

30 mm

40 mm

silica cork 150 oC

30 oC layer B

layer A

) / ( ln o i

i L o

r r

r r = r −

) 30 / 80 ( ln

30 80−

L = r

For cork layer,

) 80 / 120 ( ln

80 120−

L = r

) (

7748 . 0

) (

3522 . 0

2 ) 2

( )

(

o x B

x i A

L B

L A

B o x B B B

A x i A A A

T T L q

T T L q

L r A

L r x A

T T A q k

x T T A q k

−

=

−

=

⇒

=

− =

− =

= π π

At steady state, q = qA = qB ∴ q/L = 29.1W

Unsteady-State Conduction ( 비정상상태 열전도 )

Heat input – Heat output = Accumulation of heat

2 2

x T t

T

∂

= ∂

∂

⇒ ∂

α

thermal diffusivity (열확산계수) 단위: [m2/s]

cf.) D : mass diffusivity : kinematic viscosity

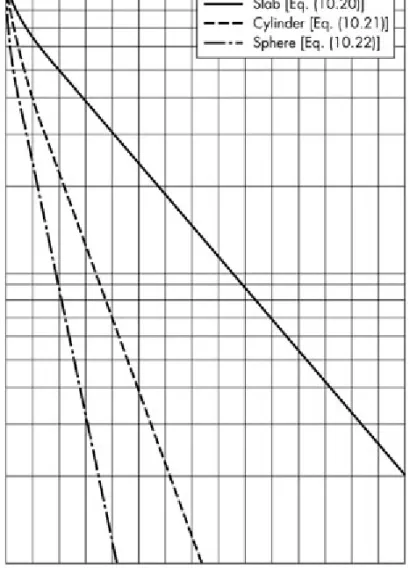

Solutions are available for certain simple shapes, such as infinite slab (Eq. 10.20), infinitely long cylinder (Eq. 10.21) and sphere (Eq. 10.22).

Æ Fig. 10.5

Cp

k

= ρ

ν

Unsteady-state conduction in solid slab

Fig. 10.5. Average temperature during unsteady-state hearing or cooling of a large slab, an infinitely long cylinder, or a sphere.