pISSN 1598-2033 eISSN 2233-5706

Journal of the Korea Institute of Building Construction, Vol. 13, No. 6

http://dx.doi.org/10.5345/JKIBC.2013.13.6.594 www.jkibc.org

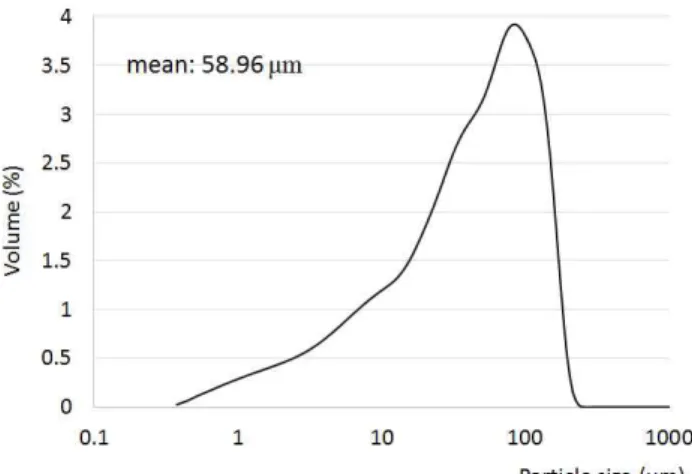

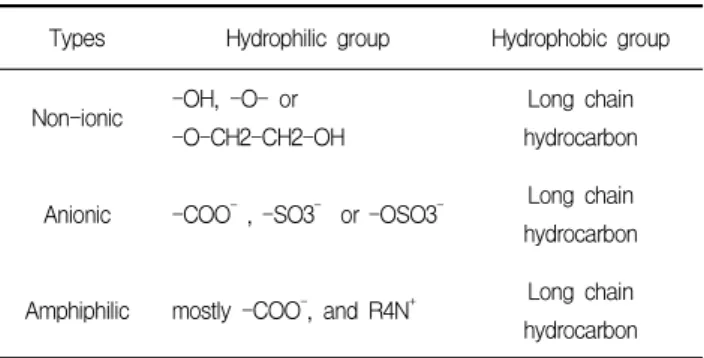

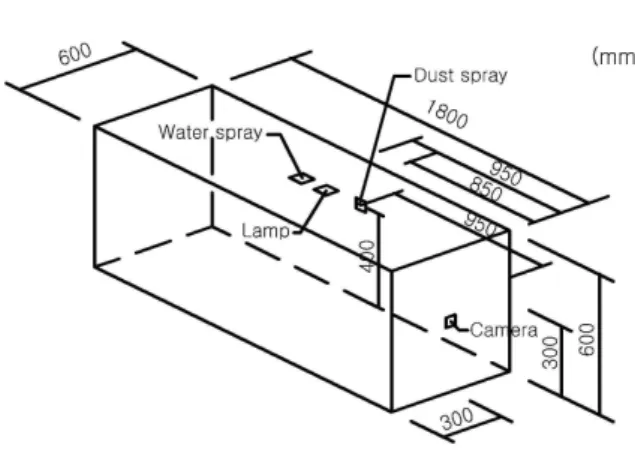

The Effect of Chemical Admixtures on Removal of Scattered Dust

1)

전체 글

pISSN 1598-2033 eISSN 2233-5706

1)

수치

관련 문서

After first field tests, we expect electric passenger drones or eVTOL aircraft (short for electric vertical take-off and landing) to start providing commercial mobility

1 John Owen, Justification by Faith Alone, in The Works of John Owen, ed. John Bolt, trans. Scott Clark, "Do This and Live: Christ's Active Obedience as the

Anoxic

Therefore, the present study aimed to (i) investigate the effect of surfactant on the solubility of valsartan and (ii) improve the dissolution profiles of valsartan

The responsibility for marine pollution control in Korea is now scattered among the Ministry of Oceans and Fisheries, the National Maritime Police

In addition, using the properties of water shown in diverse shapes, Ki Hyung-do's recognition on the reality and future consciousness from regression of

Kinematics : study of the geometry of motion. Relates displacement, velocity, acceleration, and time without reference to the cause of motion. Kinetics : study of

Summary of ANOVA on water quality and clearance rates (CR) and pseudo-feces and feces production of mussels (PFP) during the operation Continuous removal