www.journalomp.org

pISSN 2288-9272 eISSN 2383-8493 J Oral Med Pain 2019;44(2):74-76 https://doi.org/10.14476/jomp.2019.44.2.74

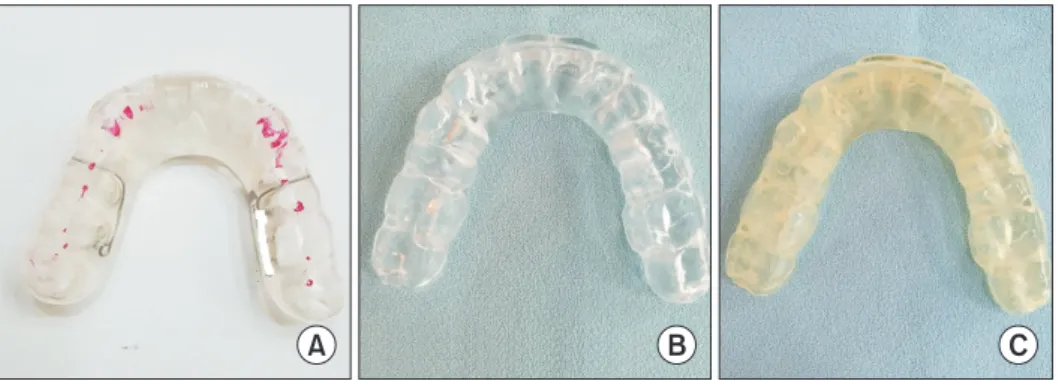

Stabilization Splint Fabrication Using Computer-Aided Design/

Computer-Aided Manufacturing and Three-Dimensional Printing

Byung-Jin Sohn 1 , Wook Kim 2 , Jea-Hong Kim 3 , Un-Bong Baik 4

1 Seoul M Dental Clinic, Seoul, Korea

2 TMD Dental Clinic, Uijeongbu, Korea

3 Seoul Top Dental Clinic, Namyangju, Korea

4 Smilewith Orthodontic Clinic, Seoul, Korea

Received June 11, 2019 Revised June 17, 2019 Accepted June 17, 2019

A conservative treatment approach to temporomandibular disorder (TMD) is recommended as the first line of management, usually with a stabilization splint. Recently, computer-aided design/computer-aided manufacturing and three-dimensional printer has been widely used in the dentistry since several years ago. The authors apply digital dentistry in oral medicine fields to make stabilization splint for TMD treatment.

Key Words: Computer-aided design/computer-aided manufacturing; Digital scanner; Stabi- lization splint; Three-dimensional printing

Correspondence to:

Wook Kim

TMD Dental Clinic, 80 Simin-ro, Uijeongbu 11651, Korea

Tel: +82-31-841-2875 Fax: +82-31-841-2864 E-mail: wkkk007@hanmail.net

https://orcid.org/0000-0002-3958-3894

Brief Communication

JOMP Journal of Oral Medicine and Pain

Copyright Ⓒ 2019 Korean Academy of Orofacial Pain and Oral Medicine. All rights reserved.

CC