Current status of the development of the

Kumgang laser

Hong Jin Kong,1,* Sangwoo Park,1 Seongwoo Cha,1 Heekyung Ahn,1 Hwihyeong Lee,1 Jungsuk Oh,1 Bong Ju Lee,2 Soungwoong Choi,2 and Jom Sool Kim3

1Department of Physics, Korean Advanced Institute of Science and Technology(KAIST), 291 Daehak-ro, Yuseong-gu,

Daejeon, 305-701 South Korea

2Department of Advanced Green Energy and Environment, Handong Global University, 558 Handong-ro, Buk-gu,

Pohang, Gyeongsangbuk-do, 791-708 South Korea

3Laser Spectronix, 219 Gasan digital 1-ro, Geumcheon-gu, Seoul, 153-704 South Korea

*hjkong@kaist.ac.kr

Abstract: The Kumgang laser, a 4 kW (4 x 0.1 J @ 10 kHz / 8.5 ns) coherent beam combination laser using self-controlled stimulated Brillouin scattering phase conjugation mirrors (SBS-PCMs), is being developed. The front-end (FE) and the pre-amplifier (PA) are completed. The FE produces pulse energy of 0.51mJ and a pulse width of 8.5 ns with a 10 kHz repetition rate (0.51mJ @ 10 kHz / 8.5 ns) and a 95 MHz linewidth. The PA amplifies up to 200 W (20 mJ @ 10 kHz / 8.5 ns) with an input power 5.1 W.

©2014 Optical Society of America

OCIS codes: (140.3480) Lasers, diode-pumped; (140.3538) Lasers, pulsed; (140.3570) Lasers,

single-mode.

References and links

1. H. J. Kong, J. S. Shin, D. H. Beak, and S. Park, “Current trends in laser fusion driver and beam combination laser systems using stimulated Brillouin scattering phase conjugate mirrors for a fusion driver,” JKPS 56(11), 177–183 (2010).

2. V. Wang and C. R. Giuliano, “Correction of phase aberrations via stimulated Brillouin scattering,” Opt. Lett.

2(1), 4–6 (1978).

3. S. K. Lee, H. J. Kong, and M. Nakatsuka, “Great improvement of phase controlling of the entirely independent stimulated Brillouin scattering phase conjugate mirrors by balancing the pump energies,” Appl. Phys. Lett.

87(16), 161109 (2005).

4. H. J. Kong, J. W. Yoon, J. S. Shin, and D. H. Beak, “Long-term stabilized two-beam combination laser amplifier with stimulated Brillouin scattering mirrors,” Appl. Phys. Lett. 92(2), 021120 (2008).

5. H. J. Kong, J. S. Shin, J. W. Yoon, and D. H. Beak, “Wave-front dividing beam combined laser fusion driver using stimulated Brillouin scattering phase conjugation mirrors,” Nucl. Fusion 49(12), 125002 (2009). 6. H. J. Kong, J. S. Shin, J. W. Yoon, and D. H. Beak, “Phase stabilization of the amplitude dividing four-beam

combined laser system using stimulated Brillouin scattering phase conjugate mirrors,” Laser Part Beams 27(01), 179–184 (2009).

7. J. S. Shin, S. Park, H. J. Kong, and J. W. Yoon, “Phase stabilization of a wave-front dividing four-beam combined amplifier with stimulated Brillouin scattering phase conjugate mirrors,” Appl. Phys. Lett. 96(13), 131116 (2010).

8. H. J. Kong, S. Park, S. Cha, and J. S. Kim, “0.4 J/10 ns/10 kHz-4 kW coherent beam combined laser using stimulated Brillouin scattering phase conjugation mirrors for industrial applications,” Phys. Status Solidi 10(6 c), 962–966 (2013).

9. T. Y. Fan, “Laser beam combining for high-power and high-radiance sources,” IEEE J. Sel. Top. Quantum Electron. 11(3), 567–577 (2005).

10. Robert Tyson, Principal of Adaptive Optics (CRC Press, 2010)

11. A. Yariv and D. M. Pepper, “Amplified reflection, phase conjugation, and oscillation in degenerate four-wave mixing,” Opt. Lett. 1(1), 16–18 (1977).

12. V. Wang and C. R. Giuliano, “Correction of phase aberrations via stimulated Brillouin scattering,” Opt. Lett.

2(1), 4–6 (1978).

13. H. J. Kong, S. Park, S. Cha, and M. Kalal, “Coherent beam combination laser system using SBS-PCM for high repetition rate solid-state lasers,” Opt. Mater. 35(4), 807–811 (2013).

14. M. J. Damzen, V. Vlad, A. Mocofanescu, and V. Babin, Stimulated Brillouin Scattering: Fundamentals and

Applications (CRC press, 2003)

15. J. S. Shin and H. J. Kong, “Phase fluctuation of self-phase-controlled stimulated Brillouin scattering waves via K8 glass,” Opt. Commun. 285(13–14), 2977–2979 (2012).

16. H. Yoshida, V. Kmetik, H. Fujita, M. Nakatsuka, T. Yamanaka, and K. Yoshida, “Heavy fluorocarbon liquids for a phase-conjugated stimulated Brillouin scattering mirror,” Appl. Opt. 36(16), 3739–3744 (1997).

17. H. Park, C. Lim, H. Yoshida, and M. Nakatsuka, “Measurement of stimulated Brillouin scattering characteristics in heavy fluorocarbon liquids and perfluoropolyether liquids,” Japanese Journal of Applied Optics 45(6A), 5073–5075 (2006).

18. H. Yoshida, A. Ohkubo, H. Fujitah, and M. Nakatsuka, “Thermally induced effects of stimulated Brillouin scattering via phase-conjugation mirror for repetitive laser pulse,” Review of Laser Engineering 29(2), 109–114 (2001).

1. Introduction

A coherent beam combining with stimulated Brillouin scattering phase conjugate mirrors (SBS-PCMs) is one of the most promising practical techniques for building a laser with high energy and a high repetition rate [1]. The coherent beam combination technique utilizes a small-gain medium that can be cooled rapidly, allowing it to operate at a high repetition rate with a high output energy level. Furthermore, the phase-conjugation property of the SBS-PCM prevents the degradation of the amplified beam quality [2]. Therefore, coherent beam combination lasers using SBS-PCMs have been studied for more than a decade, with the feasibility of these systems experimentally proved by Kong et al. [3–7].

At KAIST, the development of a 4 kW beam combination laser system using self-phase-controlled SBS-PCMs, called the “Kumgang laser,” started in 2012 and is scheduled to be completed in 2015 [8]. This paper presents the recent progress on the development of the Kumgang laser.

2. Beam Combination and Stimulated Brillouin Scattering Phase Conjugate Mirrors (SBS-PCMs)

To build a high-power laser, the size of the gain medium of the laser should be large so as not to undergo optical damage and to enlarge the stored energy. The large gain medium can have a large thermal load. To reduce the thermal load, the repetition rate of the high-power laser must be limited. Therefore, it is difficult to achieve both high power and a high repetition rate in this type of laser system.

One of the most promising techniques to resolve this thermal problem is known as coherent beam combining [1]. However, to combine laser beams coherently, the wave-front of the laser beams needs to be a plane wave-front or TEM00 mode [9]. Furthermore, the piston error between the beams should be matched [9]. To the best of our knowledge, effective methods to create a plain wave-front include the use of an adaptive optics system [10], degenerated four-wave mixing (DFWM) [11], and a phase conjugate mirror (PCM) [12]. Among numerous media, liquid media are utilized for a high-energy and high-power laser, because it is insensitive to optical damage [13].

SBS can occur in gases, liquids, and in solid materials [14, 15]. Among numerous media, liquid media are utilized for a high-energy and high-power laser, is insensitive to because it is insensitive to optical damage [13]. Specifically, fluorocarbon and perfluorinated carbon liquids have good phase-conjugation properties for a high-energy and highly repetitive laser [16, 17]. The Kumgang laser will utilize the Galden HT-70 heat transfer fluid as the SBS media for the SC-SBS-PCMs. Table 1 shows the properties of the Galden HT-70 fluid [17].

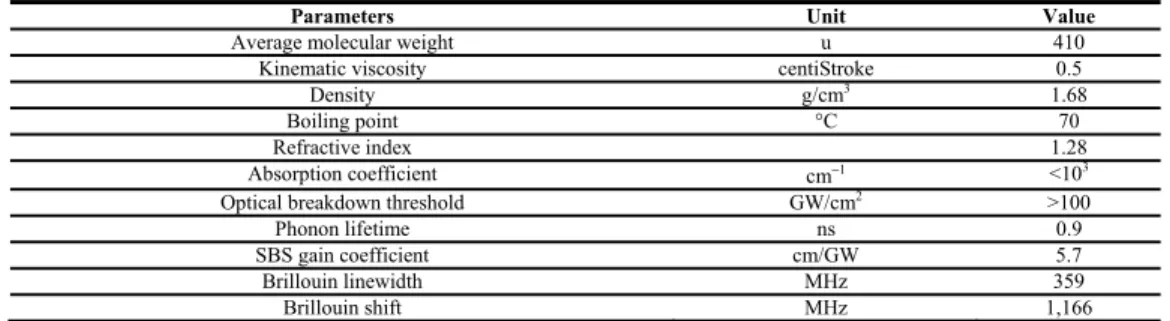

Table 1. Physical and Optical Properties of the HT-70 Fluid

Parameters Unit Value

Average molecular weight u 410 Kinematic viscosity centiStroke 0.5 Density g/cm3 1.68 Boiling point °C 70 Refractive index 1.28 Absorption coefficient cm−1 <103 Optical breakdown threshold GW/cm2 >100

Phonon lifetime ns 0.9 SBS gain coefficient cm/GW 5.7 Brillouin linewidth MHz 359 Brillouin shift MHz 1,166

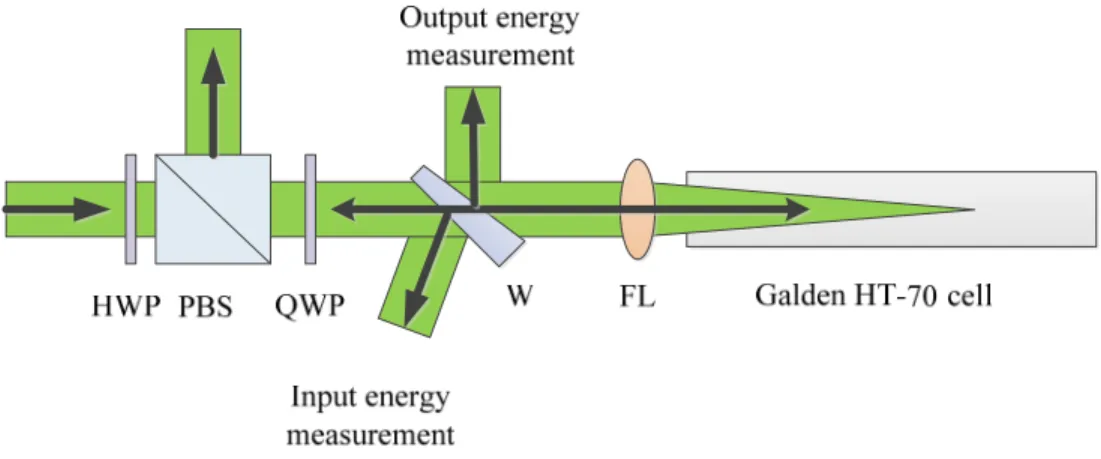

Fig. 1. The experimental setup of the reflectivity measurements of the SBS-PCM using the Galden HT-70 fluid.

Figure 1 shows the experimental setup of the reflectivity measurements of the SBS-PCM using the Galden HT-70 fluid. The laser beam from the oscillator passes through a half-wave plate (HWP), a polarizing beam splitter (PBS) and a quarter-wave plate (QWP). The beam is split by a wedged window (W), allowing the input energy to the SBS-PCM to be measured. The laser beam is focused onto a SBS cell by a focusing lens (FL). The focal length of the FL is 150 mm in this case. The beam reflected by the SBS-PCM is split by W once again, and the output beam energy is measured. The output energy of the reflected beam is calibrated with a conventional mirror.

Figure 2 shows the reflectivity of the SBS-PCM using the Galden HT-70 fluid due to the input energy of the laser beam. This figure shows that the reflectivity of the HT-70 exceeds 50% when the input energy is greater than 10 mJ. This result implies that the input energy of the main amplifiers in the beam combination laser system should be greater than 10 mJ for an efficient beam combination.

To apply this PCM to the Kumgang laser, the input power limitation of the SBS-PCMs should be considered. According to Yoshida et al. [18], a high-power laser beam is absorbed by SBS media, with thermal lensing and convection occurring in the SBS media. These effects reduce the focal spot intensity of the beam. As a result, the reflectivity of the SBS-PCM is decreased. The SBS-PCMs for the Kumgang laser has been specially designed to reduce the thermal effect caused by the high input power.

0 50 100 150 200 250 -10 0 10 20 30 40 50 60 70 80 90 100

Reflectivity (%)

Input Energy (mJ)

10 mJFig. 2. The reflectivity of the Galden HT-70 fluid given the input energy.

3. A 4 kW Coherent beam combination laser system using self-controlled SBS-PCMs

Fig. 3. A schematic diagram of the Kumgang laser system.

Figure 3 shows a schematic diagram of the Kumgang laser. The front-end (FE) produces a single-frequency seed beam of 1064 nm at a repetition rate of 10 kHz. The average output power of the FE is 5.1 W (0.51 mJ @ 10 kHz / 8.5 ns). The seed laser beam from the FE is amplified by a pre-amplifier (PA) from 5.1 W (0.51 mJ @ 10 kHz / 8.5 ns) to 200 W (20 mJ @ 10 kHz / 8.5 ns). The gain medium of the PA is an Nd:YAG rod. After the amplification process by the PA, the laser beam will be divided into four sub-beams by a coherent beam divider/combiner for its main amplification. This will be operational within one year. The wave-front distortion of each sub-beam can be compensated for by SBS-PCMs [2]. After the reflection at the SBS-PCMs and after passing through the main amplifier module (MA) again, the sub-beams will be combined by the coherent beam divider/combiner. Each sub-beam will be amplified by the MA to obtain a laser output of 1 kW (0.1 J @ 10 kHz / 8.5 ns). As a

result, the average output power of each sub-beam will be 1 kW (0.1 J @ 10 kHz / 8.5 ns). The total coherently combined output power is expected to be 4 kW (0.4 J @ 10 kHz / 8.5 ns). Table 2 presents a summary of the primary design parameters, criteria, and current status of each part of the Kumgang laser.

Table 2. A Summary of the Design Parameters, Criteria, and Current Status of the Kumgang Laser System

Part Design parameters Criteria Current status

Front-end Rep. rate (kHz) 10 10

Linewidth (MHz) <359 95

Pulse width (ns) <10 8.5

Output power (W) >3 5.1

Wavelength tuning range (nm) 1 1

Pre-amplifier Output power (W) >200 200

Main amplifier module Output power (W) >1,000 -

4. Single-frequency hybrid-Master-Oscillator Power Amplifier (MOPA) front-end

Fig. 4. A schematic diagram of the FE: LD, the single-frequency diode laser oscillator; FC/APC, the fiber connector/angled physical contact; AOM, the acousto-optic modulator; WDM, the wavelength-division multiplexor; Yb-fiber, the Yb-doped fiber amplifier; BPF, the band-pass filter; FC, the fiber collimator; HWP1 and HWP2, half-wave plates; PBS, the polarizing beam splitter; FR1 and FR2, Faraday rotators; TFP1 and TFP2, thin-film polarizers; PC, the Pockels cell; QWP, the quarter-wave plate; HR1 and HR2; high reflectors; A1 and A2, apertures; and GM, the Nd:YAG rod gain module.

Figure 4 shows a schematic diagram of the FE of the Kumgang laser. The FE is the single-frequency hybrid master-oscillator power amplifier (MOPA) system. The master oscillator [MO] consists of a diode laser oscillator (LD), an acousto-optic modulator (AOM), a pump LD, a wavelength-division multiplexor (WDM), a Yb-doped fiber amplifier (Yb fiber), and a band-pass filter (BPF). The LD produces a CW single-frequency seed beam. The CW laser beam from this LD is shaped to have a pulse width of 10 ns and a 10 kHz repetition rate by the AOM. The laser beam is then amplified by the Yb fiber and passes through the BPF. The output power of the FE is 100 μW (10 nJ @ 10 kHz / 9.5 ns).

Nd:YAG rod-regenerative amplifier (RA) amplifies the output beam of the MO to 5.1 W (0.51 mJ @ 10 kHz / 8.5 ns). The output beam of the MO is collimated by a fiber collimator (FC) and travels from the Faraday rotator (FR1) to the half-wave plate (HWP2). After passing

through HWP2, the beam is injected into the RA cavity, as indicated by the dotted line. The RA cavity consists of thin-film polarizers (TFP1 and TFP2), a Pockels cell (PC), a quarter-wave plate (QWP), an Nd:YAG gain module (GM), apertures (A1 and A2), and high reflectors (HR1 and HR2). A PC high-voltage driver operates at a quarter-wave rotation voltage level when the PC is activated. When the seed beam is injected into the RA cavity, the beam is trapped inside the RA cavity by the activated PC. After 30 round trips, the beam is dumped out of the RA cavity by the deactivated PC. The output beam from the RA cavity passes through HWP2 and FR2 and is reflected out by the PBS.

FSR=7.5GHz

Single-frequencyFabry-Perot fringe Scan voltage

Single frequency line-width MHz FSR 1500MHz FWHM 95MHz (A) (B)

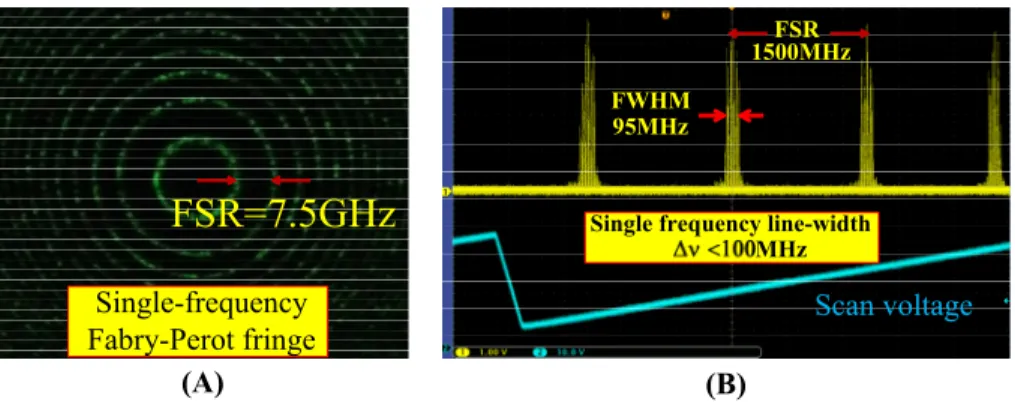

Fig. 5. (a) A Fabry-Perot interferogram of the output beam of the RA, and (b) the interference spectrum of the output beam of the RA measured by the scanning Fabry-Perot interferometer.

With a Fabry-Perot interferometer, the spectral line shape of the RA laser beam is obtained, as shown in Fig. 5(a), which shows the single-frequency operation. The measured linewidth of the output beam of the RA was 95 MHz, as shown in Fig. 5(b). Figure 6(a) and 6(b) show the pulse shape of the leak pulse of the RA and the output pulse of the RA, respectively. The pulse width is tunable from 5 ns to 10 ns by controlling the activation timing of the PC with a delay/pulse generator; it is typically 8.5 ns in this experiment. Figure 6(c) shows the output beam profile of the RA.

Fig. 6. (a) The pulse shape of the RA cavity leak pulse, (b) the output pulse shape of the RA, and (c) the output beam profile of the RA.

To optimize the amplification with Nd:YAG rod amplifiers, it is necessary to fit the center wavelength of the FE to the gain curve of the Nd:YAG rod amplifiers. By tuning the temperature and the pumping current of the LD, the wavelength of the FE can be tuned to a wavelength range of 1 nm. Figure 7 shows the output wavelength of the LD as a function of the temperature of the LD with 100.0 mA of pumping.

Linewidth <7.5MHz (resolution limit) Temp scan ~200MHz/0.01C FSR=1500MHz 1064 1064.2 1064.4 1064.6 1064.8 1065 1065.2 16 18 20 22 24 26 28 30 C enter Wa veleng th (nm) LD Temperature (C) @ LD Current=100.0mA LD Spectrum

Fig. 7. The center wavelength of the output beam of LD as a function of the LD temperature.

Figure 8 shows the output power of the RA. The output power is 5.1 W (0.51 mJ @ 10 kHz / 8.5ns), and the power fluctuation is 0.49% during a time of one hour.

Output

po

wer

(W

)

Fig. 8. The output power of the RA during a time of one hour.

5. Nd:YAG Rod Pre-Amplifier

Fig. 9. A schematic diagram of the PA: FE, the front-end; FI, the Faraday isolator; PBS, the polarizing beam splitter; RL1~4, image relaying lenses; GM1~3, Nd:YAG gain modules; PR, the polarization rotator; FR, the Faraday rotator; HR, the high reflector; and A and B, measurement points.

The Nd:YAG rod PA has been built and tested. Figure 9 shows the setup of the Nd:YAG rod PA. The beam from the FE passes through the Faraday isolator (FI) and is reflected at the polarizing beam splitter (PBS). After reflection at the PBS, the beam travels back and forth inside the PA and is amplified twice. After the amplification process by the PA, the output beam passes out through the PBS.

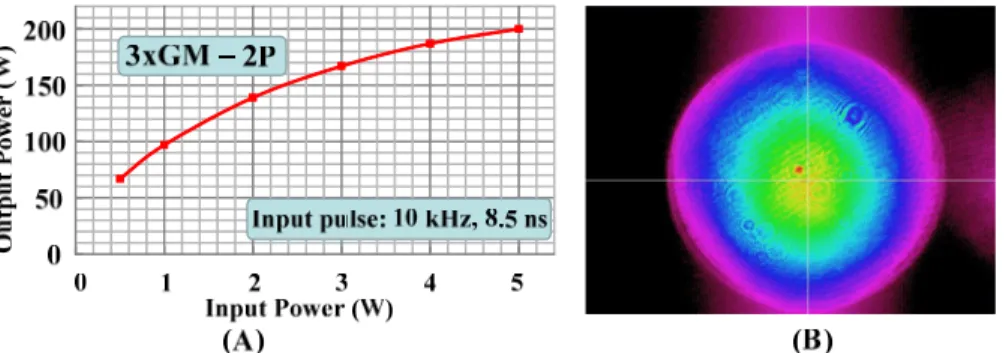

Figure 10(a) shows the output power of the PA as measured at point B in Fig. 7 as a function of the input power measured at point A in Fig. 7. The measured output power was 200 W (20 mJ @ 10 kHz / 8.5 ns) with an input power of 5.1 W (0.51 mJ @ 10 kHz / 8.5 ns).

Figure 10(b) shows the output beam profile of the Nd:YAG rod PA. This good output beam profile was obtained with the help of an image relaying system.

Fig. 10. (a) The output power of the PA at point B as a function of the input power measured at point A, and (b) the output beam profile of the PA.

6. Conclusion

In this paper, the authors successfully demonstrated the single-frequency hybrid MOPA FE and Nd:YAG rod PA of the Kumgang laser. The FE produces a 10 kHz pulse laser beam which has a pulse width of 8.5 ns and a linewidth of 95 MHz. The PA can amplify laser beams to 200 W (20 mJ @ 10 kHz / 8.5 ns) with an input power 5.1 W (0.51 mJ @ 10 kHz / 8.5 ns). With this FE and PA, the Kumgang laser will be completed by the middle of 2015. The Kumgang laser will be applied to cut a micro-SD RAM card using a hologram, which will be a new form of machining technology in the future. This technology will be more reproducible, more fast and efficient than the conventional scanning method, because it does not need scanning of the focused laser beam.

Acknowledgment

This work was supported by the “Dual-Use Technology Program” at the Agency for Defense Development (ADD) of the Republic of Korea (UM12012RD1) and by the National R&D Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2013-036083).